Innovation in a Production Process

Gallery

Award

Innovation in a Production Process

Boat Builders Awards

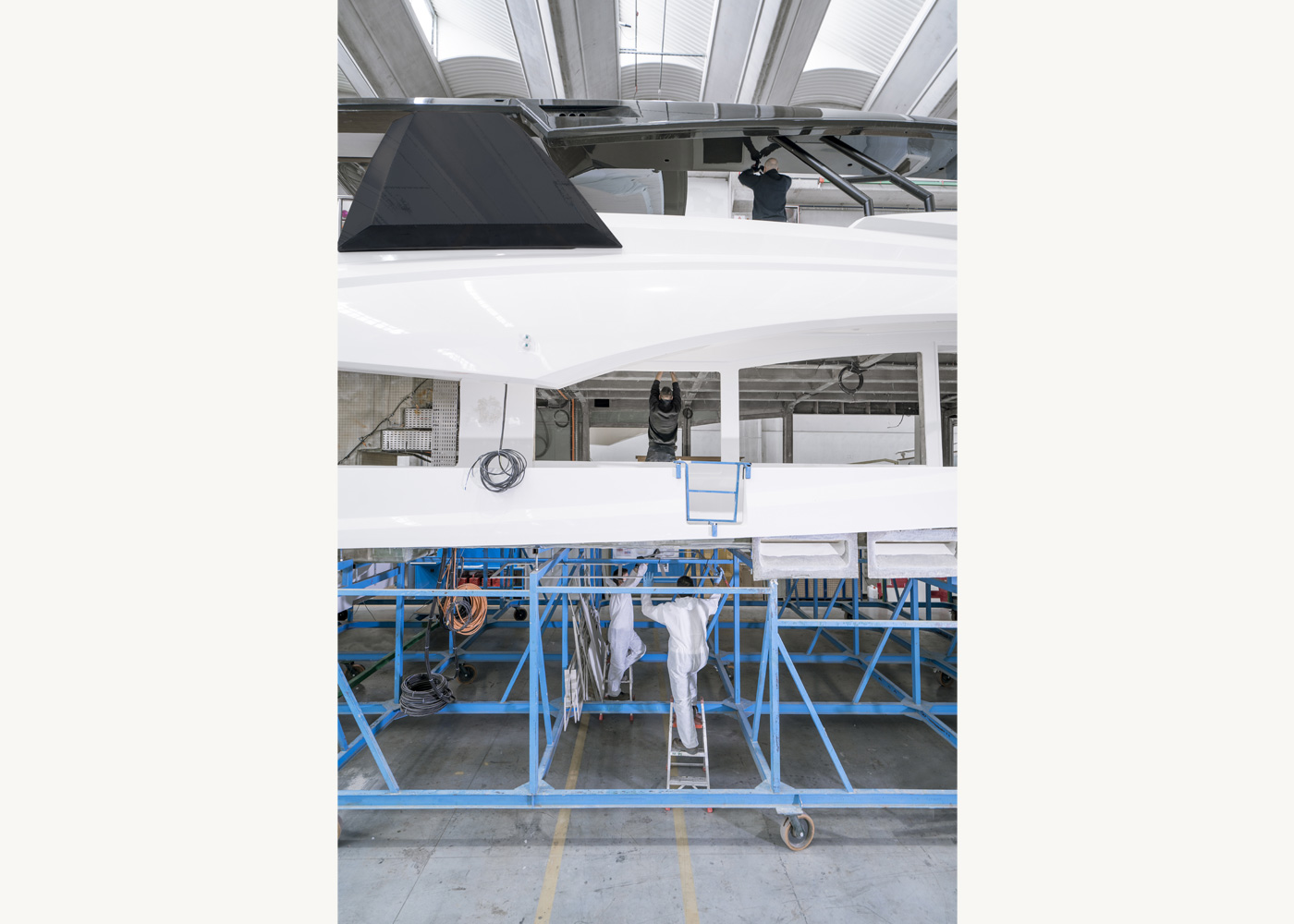

"Monte Carlo Yachts’ modular construction system is a game-changer for the industry. Monte Carlo Yachts’ ability to construct interiors outside of the boat on a grid system not only greatly simplifies the building process, but also encourages more exact levels of finish, enabling much greater levels of customisation-in essence Monte Carlo Yachts has cracked the code of building semi-custom boats on a full scale series production line. The MCY collection bares testimony to a builder redefining the rules."

IBI-METS panel statement

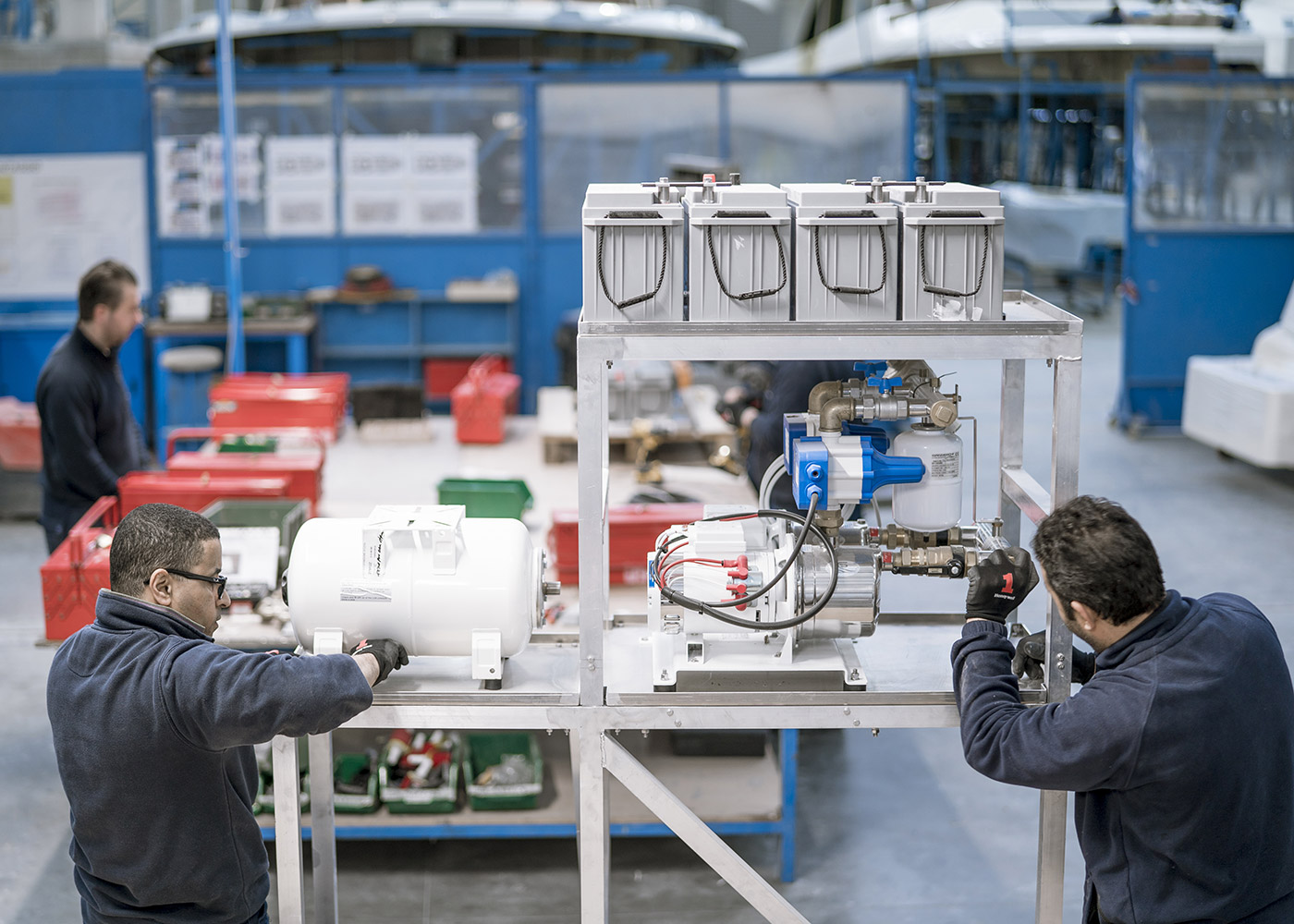

Key features

CUSTOMIZATION

What may come to a surprise at first is discovering that Monte Carlo Yachts builds fiberglass boats where virtually every inch of space is custom-designed and hand-made. All materials used in the yachts’ living spaces come from the world’s top design firms. Leveraging technology both within the design and manufacturing process, the MCY collection offers limitless customization possibilities to satisfy any owner’s special requirements.

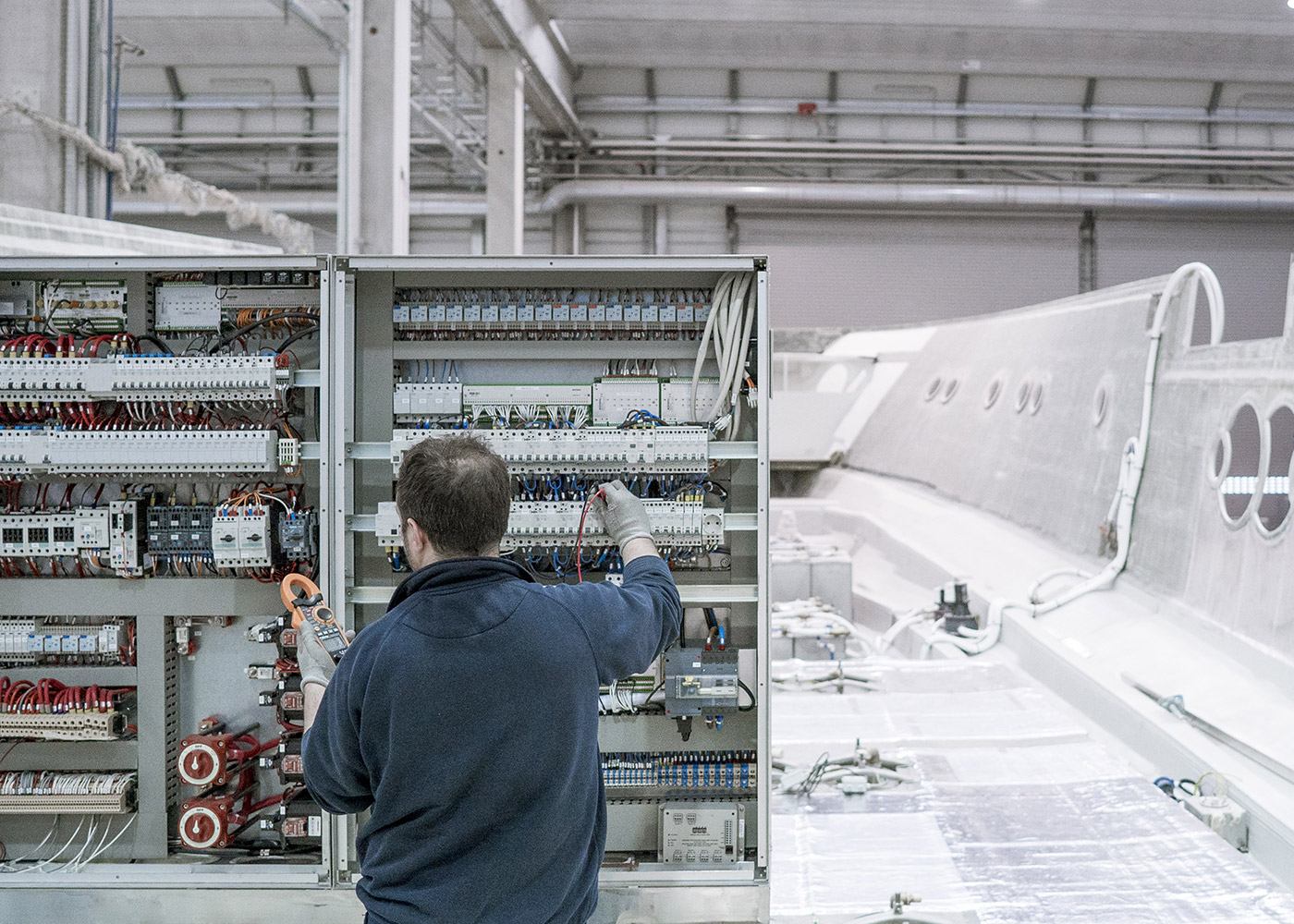

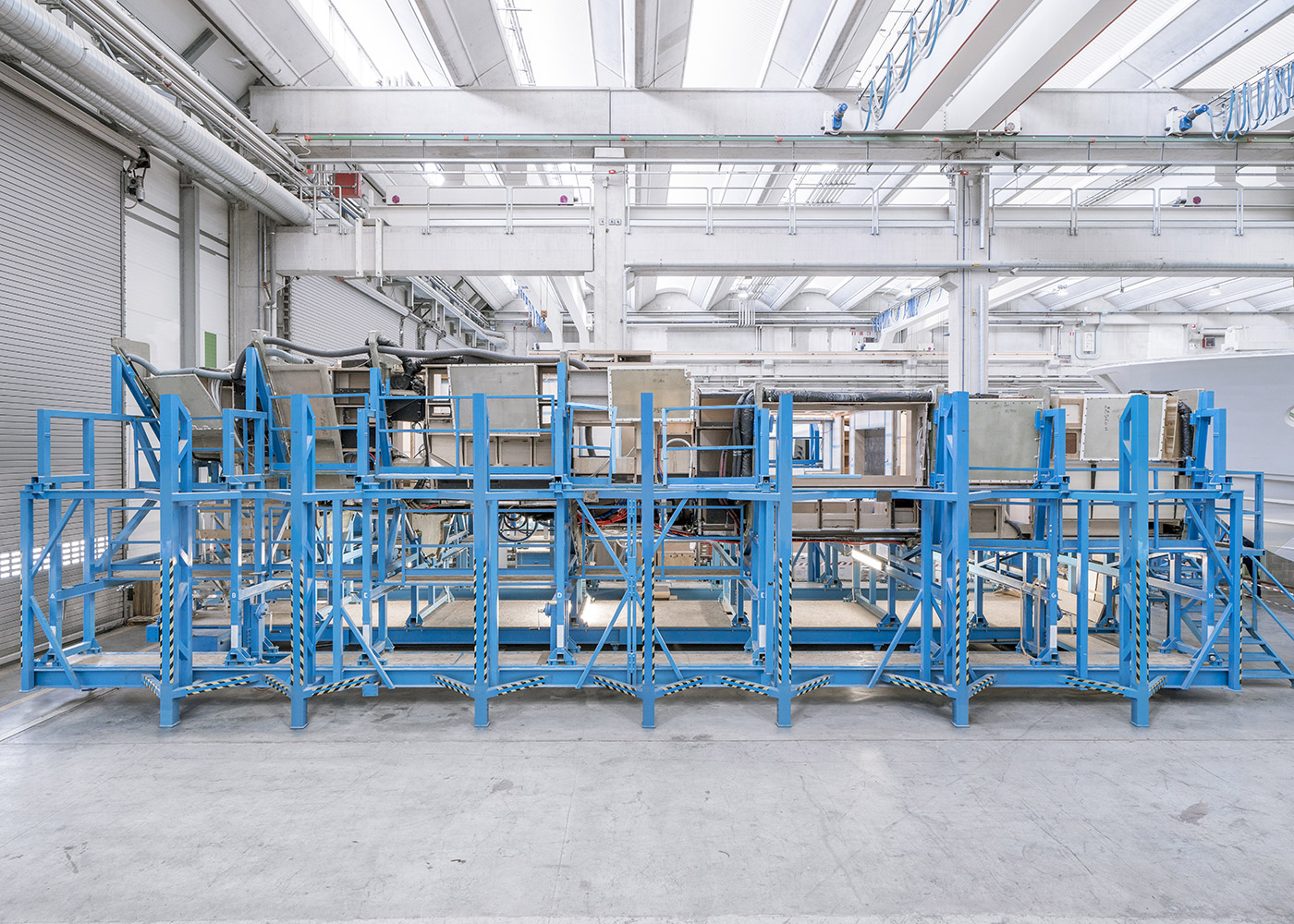

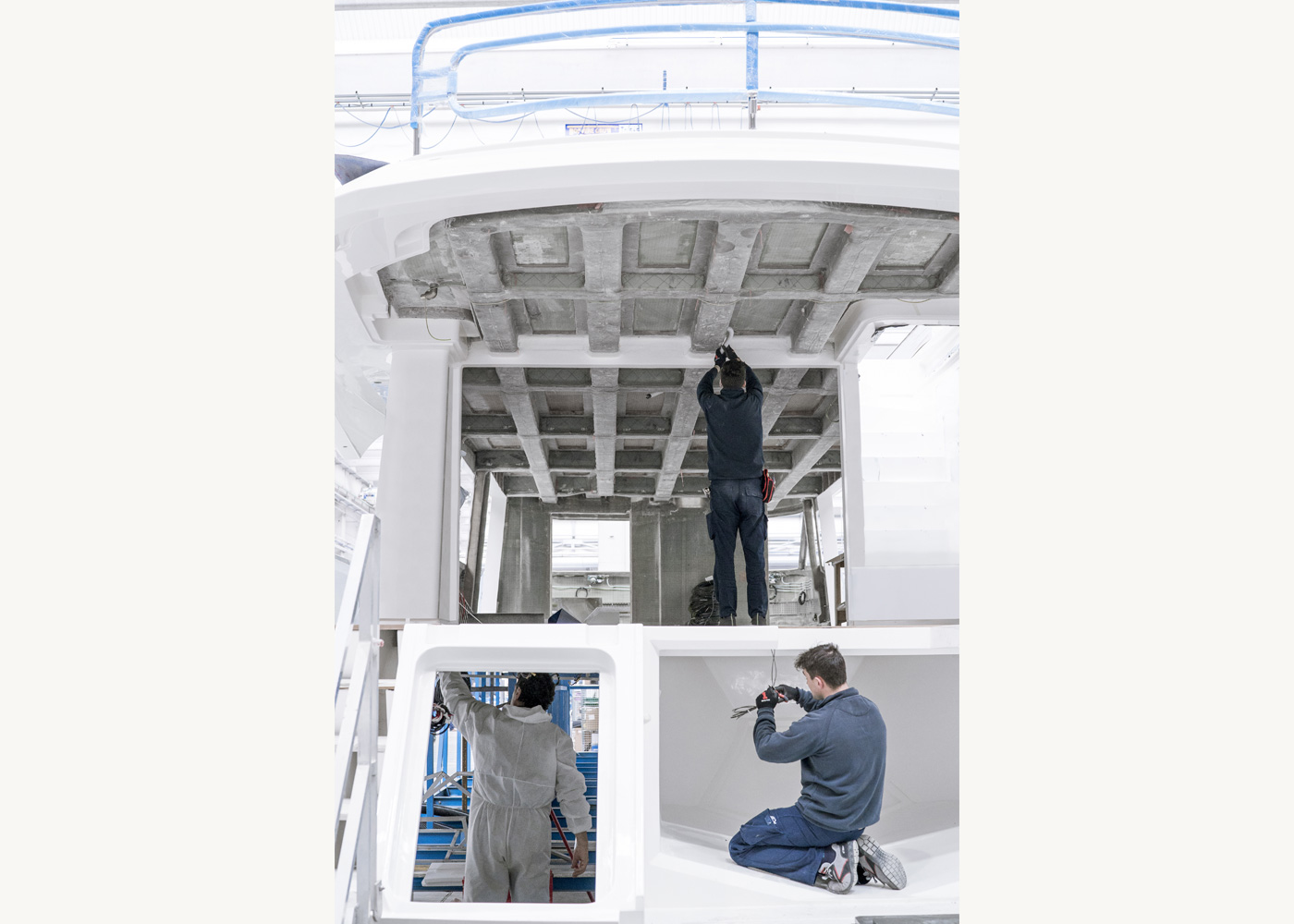

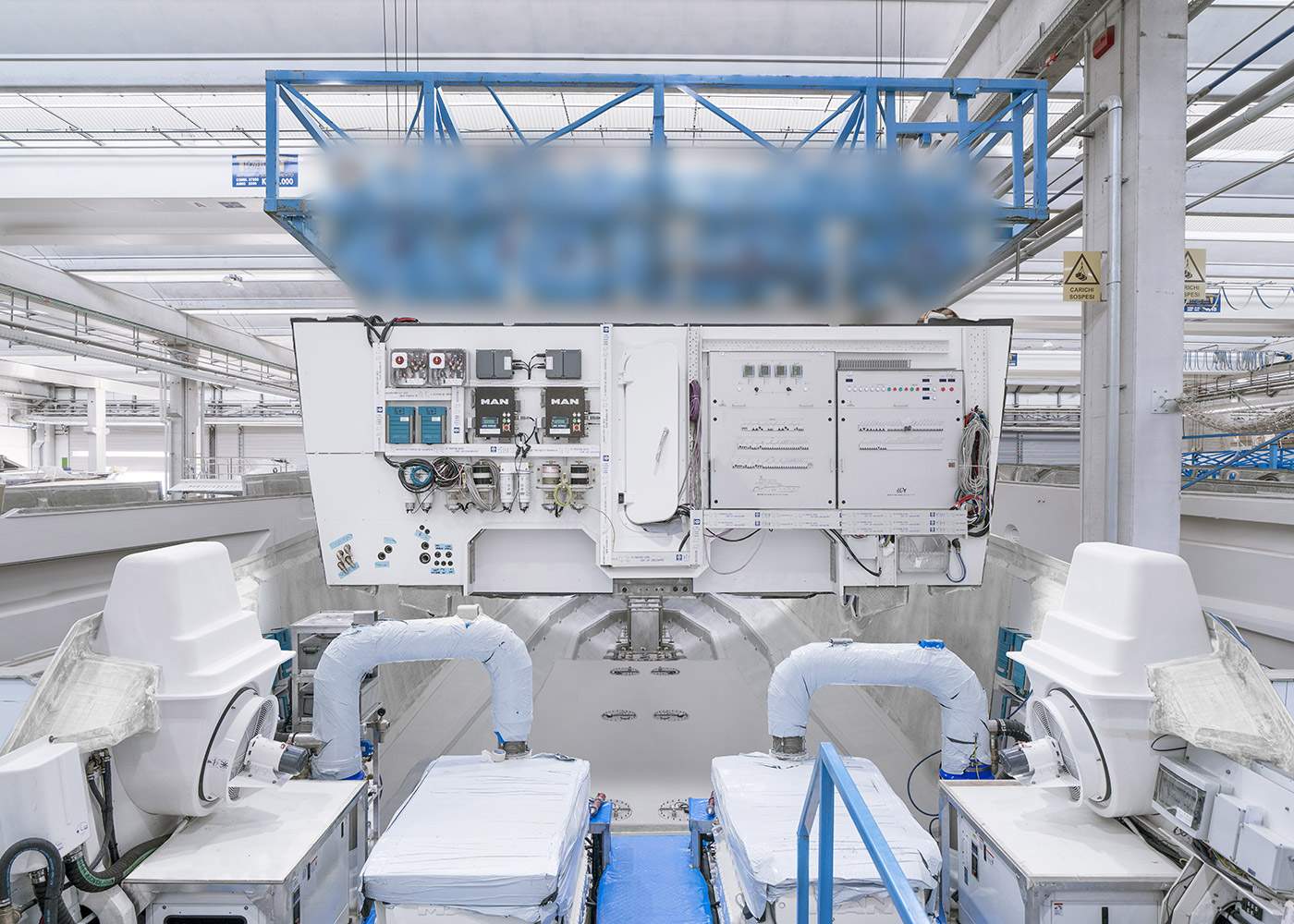

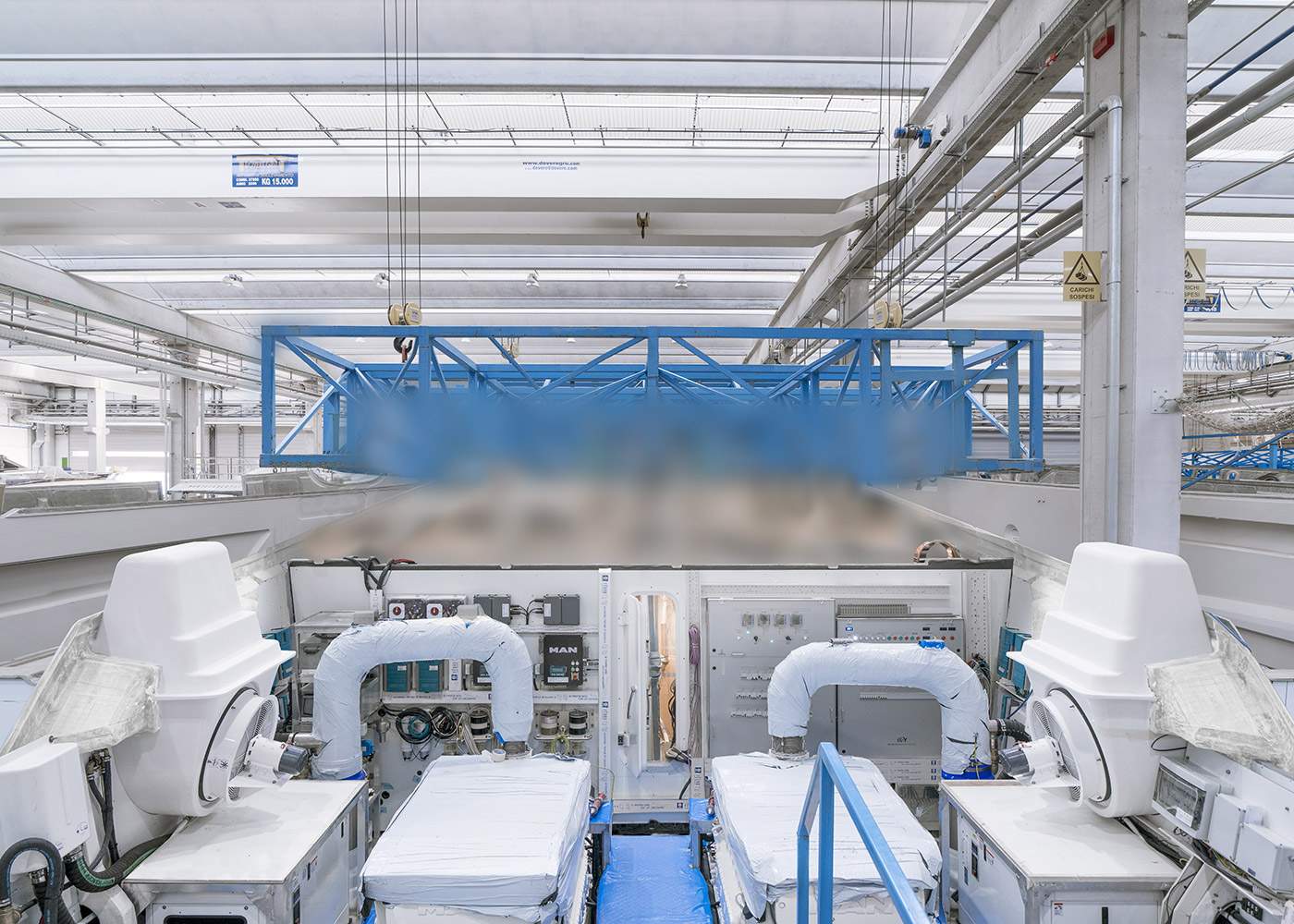

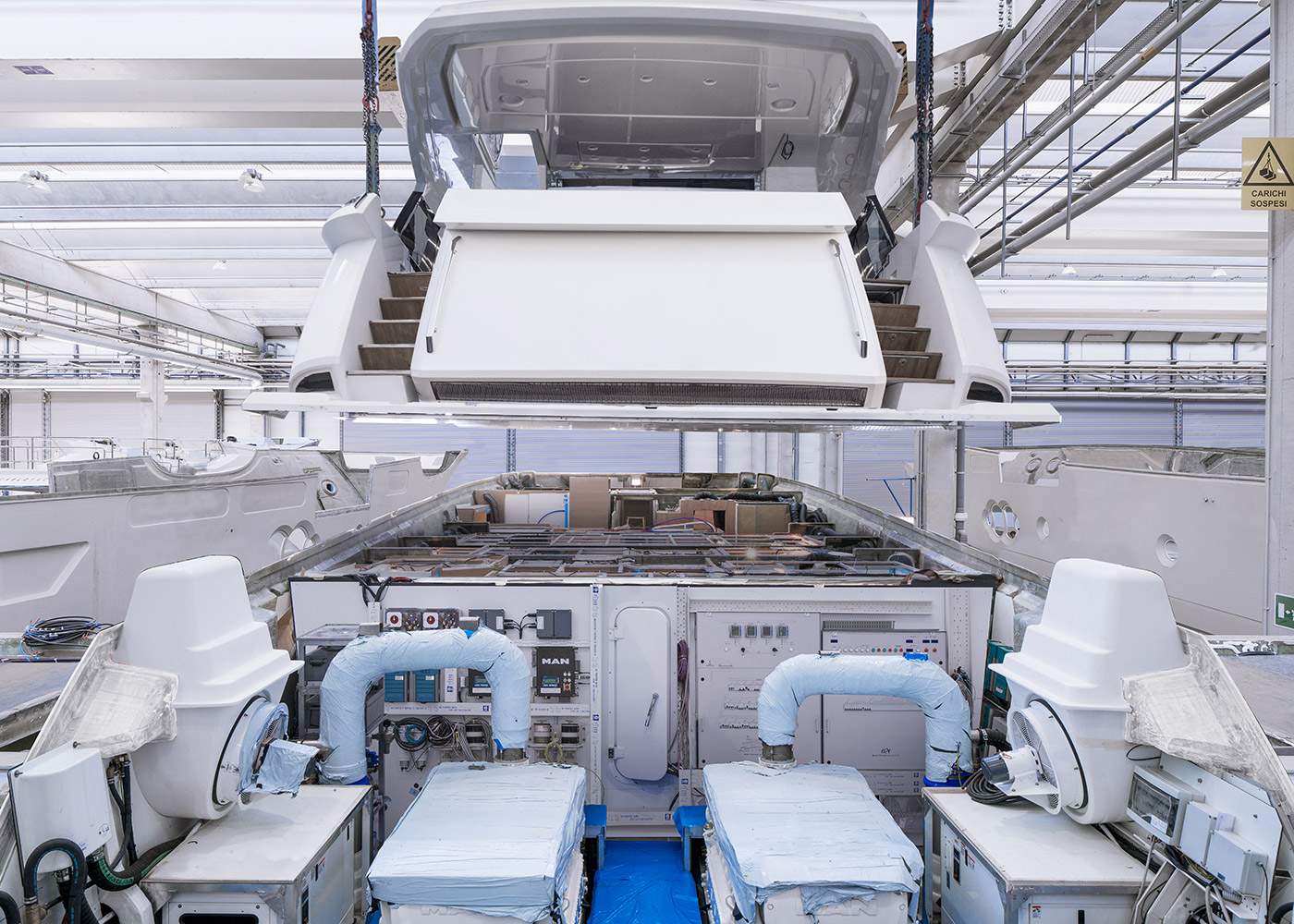

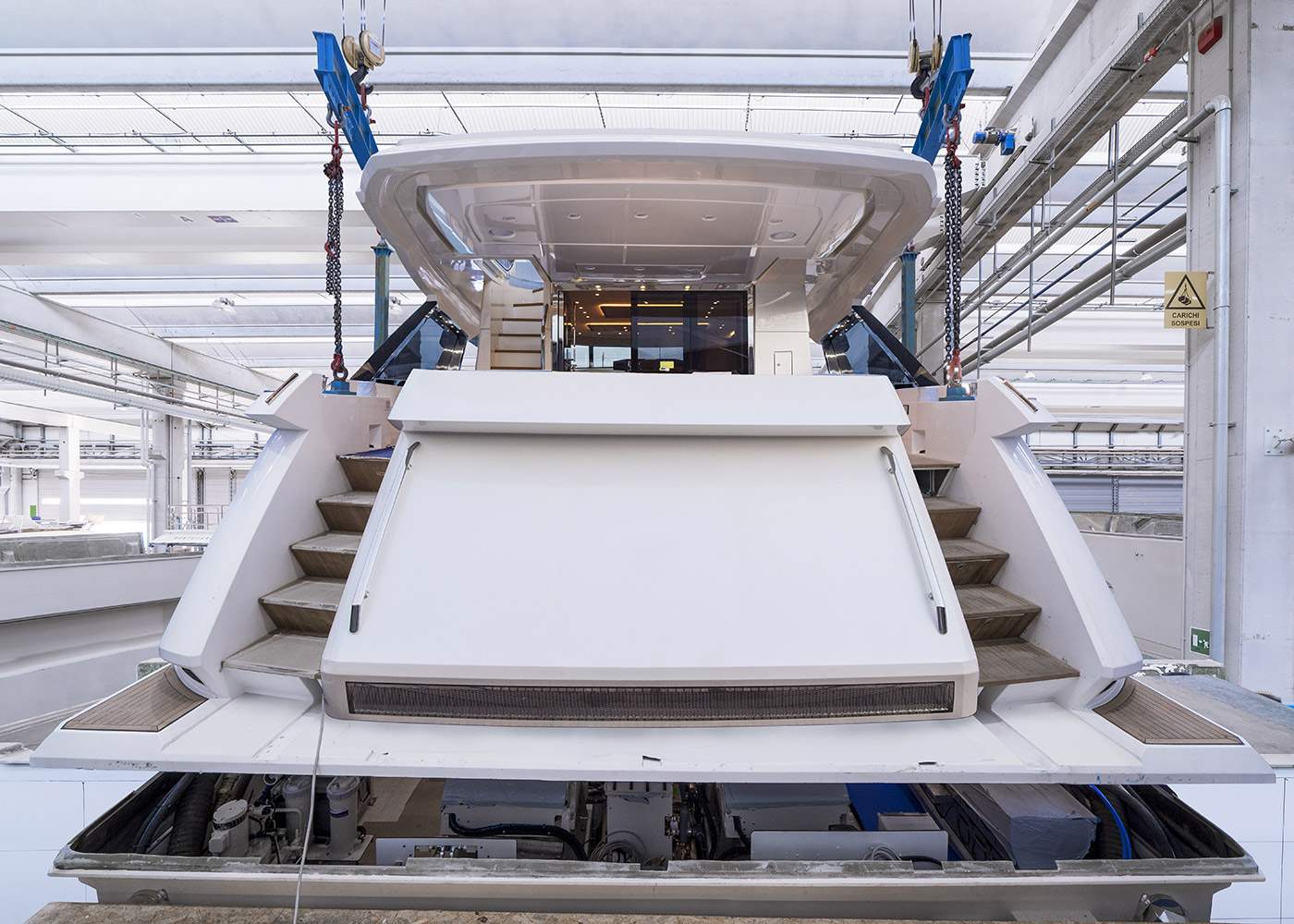

NAVAL ARCHITECTURE AND PRODUCTION PROCESS

Inspired by Lean Manufacturing concepts and the aerospace industry, Monte Carlo Yachts manufacturing process constitutes an extraordinarily innovative approach in the yachting sector. MCY yachts are made of three modules – HULL, INTERIOR MODULE AND DECK - which are built simultaneously until the last detailing stage then joined together during final assembly. The truly innovative element is represented by the interior module, which is built in its entirety as a single piece out of the hull. While the traditional hull structure is replaced by an innovative internal structural skeleton so that the entire beam of the yacht contributes to increase the structural qualities of the boat.

GRP COMPONENTS AND INFUSION PROCESS

All fiberglass components of every MCY yacht are meticulously manufactured using engineered core materials and resin applied by vacuum infusion. This choice provides for a better work environment thanks to adrastic reduction in the levels of emissions in the air. While also reducing the yacht’s weight through an optimization of the impregnation ratios of the composite. Almost unique in the sector, all fiberglass components used receive a special post-curing treatment before going to the assembly line, guaranteeing the best mechanical and physical properties. This procedure is performed inside the company's state-of-the-art painting facility which doubles as an oven running high temperature.

Press reviews